How Does an Old Fashioned Water Pump Work

A pocket-sized, electrically powered pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries,[1] past mechanical action, typically converted from electrical free energy into hydraulic energy. Pumps can exist classified into three major groups co-ordinate to the method they utilise to movement the fluid: direct elevator, displacement, and gravity pumps.[ii]

Pumps operate by some mechanism (typically reciprocating or rotary), and consume free energy to perform mechanical work moving the fluid. Pumps operate via many free energy sources, including manual performance, electricity, engines, or air current power, and come in many sizes, from microscopic for use in medical applications, to big industrial pumps.

Mechanical pumps serve in a wide range of applications such every bit pumping h2o from wells, aquarium filtering, pond filtering and aeration, in the automobile industry for water-cooling and fuel injection, in the energy industry for pumping oil and natural gas or for operating cooling towers and other components of heating, ventilation and air conditioning systems. In the medical industry, pumps are used for biochemical processes in developing and manufacturing medicine, and equally bogus replacements for trunk parts, in particular the artificial heart and penile prosthesis.

When a casing contains only i revolving impeller, information technology is chosen a single-stage pump. When a casing contains two or more revolving impellers, information technology is called a double- or multi-stage pump.

In biology, many different types of chemic and biomechanical pumps have evolved; biomimicry is sometimes used in developing new types of mechanical pumps.

Types [edit]

Mechanical pumps may be submerged in the fluid they are pumping or exist placed external to the fluid.

Pumps can exist classified past their method of displacement into positive-deportation pumps, impulse pumps, velocity pumps, gravity pumps, steam pumps and valveless pumps. In that location are three basic types of pumps: positive-displacement, centrifugal and centric-menstruum pumps. In centrifugal pumps the direction of period of the fluid changes past ninety degrees as information technology flows over impeller, while in centric menstruation pumps the management of menses is unchanged.[3]

Positive-deportation pumps [edit]

A positive-displacement pump[4] makes a fluid move by trapping a fixed amount and forcing (displacing) that trapped volume into the belch pipe.

Some positive-deportation pumps utilize an expanding cavity on the suction side and a decreasing cavity on the discharge side. Liquid flows into the pump as the cavity on the suction side expands and the liquid flows out of the discharge every bit the cavity collapses. The volume is constant through each cycle of operation.

Positive-displacement pump behavior and safe [edit]

Positive-displacement pumps, unlike centrifugal, can theoretically produce the same flow at a given speed (rpm) no matter what the discharge force per unit area. Thus, positive-displacement pumps are constant flow machines. However, a slight increase in internal leakage as the pressure level increases prevents a truly constant flow charge per unit.

A positive-deportation pump must non operate confronting a closed valve on the belch side of the pump, because it has no shutoff head similar centrifugal pumps. A positive-displacement pump operating against a closed discharge valve continues to produce menstruation and the pressure level in the discharge line increases until the line bursts, the pump is severely damaged, or both.

A relief or safe valve on the discharge side of the positive-displacement pump is therefore necessary. The relief valve can be internal or external. The pump manufacturer normally has the option to supply internal relief or safety valves. The internal valve is unremarkably used only as a safety precaution. An external relief valve in the discharge line, with a return line back to the suction line or supply tank provides increased safe of human and equipment both.

Positive-displacement types [edit]

A positive-displacement pump can be farther classified according to the mechanism used to move the fluid:

- Rotary-type positive displacement: internal or external gear pump, spiral pump, lobe pump, shuttle block, flexible vane or sliding vane, circumferential piston, flexible impeller, helical twisted roots (e.g. the Wendelkolben pump) or liquid-ring pumps

- Reciprocating-type positive displacement: piston pumps, plunger pumps or diaphragm pumps

- Linear-blazon positive displacement: rope pumps and chain pumps

Rotary positive-displacement pumps [edit]

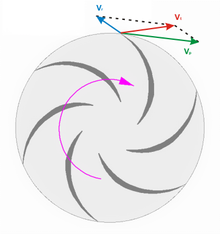

These pumps move fluid using a rotating mechanism that creates a vacuum that captures and draws in the liquid.[5]

Advantages: Rotary pumps are very efficient[half dozen] because they can handle highly mucilaginous fluids with higher flow rates equally viscosity increases.[7]

Drawbacks: The nature of the pump requires very shut clearances betwixt the rotating pump and the outer edge, making it rotate at a irksome, steady speed. If rotary pumps are operated at high speeds, the fluids cause erosion, which eventually causes enlarged clearances that liquid tin pass through, which reduces efficiency.

Rotary positive-displacement pumps fall into 5 master types:

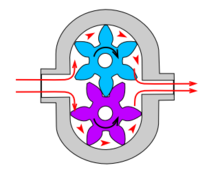

- Gear pumps – a unproblematic type of rotary pump where the liquid is pushed around a pair of gears.

- Spiral pumps – the shape of the internals of this pump is ordinarily ii screws turning confronting each other to pump the liquid

- Rotary vane pumps

- Hollow deejay pumps (also known equally eccentric disc pumps or Hollow rotary disc pumps), similar to gyre compressors, these take a cylindrical rotor encased in a round housing. As the rotor orbits and rotates to some degree, it traps fluid betwixt the rotor and the casing, drawing the fluid through the pump. It is used for highly viscous fluids like petroleum-derived products, and information technology tin likewise support high pressures of up to 290 psi.[8] [9] [10] [11] [12] [13] [xiv]

- Vibratory pumps or vibration pumps are like to linear compressors, having the aforementioned operating principle. They work past using a spring-loaded piston with an electromagnet continued to AC current through a diode. The spring-loaded piston is the just moving part, and it is placed in the middle of the electromagnet. During the positive bike of the Air-conditioning electric current, the diode allows energy to pass through the electromagnet, generating a magnetic field that moves the piston backwards, compressing the spring, and generating suction. During the negative bicycle of the Ac current, the diode blocks current flow to the electromagnet, letting the leap uncompress, moving the piston forward, and pumping the fluid and generating pressure level, similar a reciprocating pump. Due to its low toll, it is widely used in cheap espresso machines. However, vibratory pumps cannot exist operated for more than one minute, as they generate large amounts of heat. Linear compressors do not have this problem, as they can exist cooled past the working fluid (which is often a refrigerant).[xv] [16]

Reciprocating positive-deportation pumps [edit]

Antique "pitcher" pump (c. 1924) at the Colored School in Alapaha, Georgia, The states

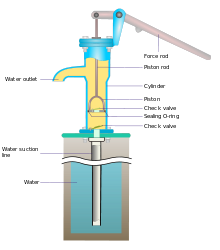

Reciprocating pumps move the fluid using one or more oscillating pistons, plungers, or membranes (diaphragms), while valves restrict fluid motion to the desired management. In order for suction to take place, the pump must first pull the plunger in an outward motion to decrease force per unit area in the chamber. Once the plunger pushes back, it will increase the chamber pressure level and the inward pressure of the plunger will then open the discharge valve and release the fluid into the delivery pipe at constant flow rate and increased pressure.

Pumps in this category range from simplex, with one cylinder, to in some cases quad (four) cylinders, or more. Many reciprocating-type pumps are duplex (two) or triplex (3) cylinder. They tin exist either single-acting with suction during ane management of piston movement and belch on the other, or double-acting with suction and discharge in both directions. The pumps can be powered manually, by air or steam, or by a belt driven by an engine. This type of pump was used extensively in the 19th century—in the early days of steam propulsion—as banality feed water pumps. At present reciprocating pumps typically pump highly gummy fluids like physical and heavy oils, and serve in special applications that need depression menses rates against high resistance. Reciprocating hand pumps were widely used to pump water from wells. Common bicycle pumps and pes pumps for inflation employ reciprocating action.

These positive-displacement pumps have an expanding cavity on the suction side and a decreasing crenel on the discharge side. Liquid flows into the pumps every bit the cavity on the suction side expands and the liquid flows out of the discharge as the cavity collapses. The volume is constant given each cycle of operation and the pump'south volumetric efficiency tin can be achieved through routine maintenance and inspection of its valves.[17]

Typical reciprocating pumps are:

- Plunger pumps – a reciprocating plunger pushes the fluid through 1 or two open valves, airtight by suction on the way back.

- Diaphragm pumps – similar to plunger pumps, where the plunger pressurizes hydraulic oil which is used to flex a diaphragm in the pumping cylinder. Diaphragm valves are used to pump chancy and toxic fluids.

- Piston pumps displacement pumps – usually simple devices for pumping minor amounts of liquid or gel manually. The common hand soap dispenser is such a pump.

- Radial piston pumps - a form of hydraulic pump where pistons extend in a radial direction.

Various positive-displacement pumps [edit]

The positive-displacement principle applies in these pumps:

- Rotary lobe pump

- Progressive cavity pump

- Rotary gear pump

- Piston pump

- Diaphragm pump

- Spiral pump

- Gear pump

- Hydraulic pump

- Rotary vane pump

- Peristaltic pump

- Rope pump

- Flexible impeller pump

Gear pump [edit]

This is the simplest form of rotary positive-displacement pumps. It consists of two meshed gears that rotate in a closely fitted casing. The tooth spaces trap fluid and forcefulness it effectually the outer periphery. The fluid does not travel dorsum on the meshed part, because the teeth mesh closely in the center. Gear pumps meet wide use in car engine oil pumps and in diverse hydraulic power packs.

Spiral pump [edit]

A screw pump is a more complicated type of rotary pump that uses two or three screws with opposing thread — e.g., one screw turns clockwise and the other counterclockwise. The screws are mounted on parallel shafts that have gears that mesh so the shafts plow together and everything stays in place. The screws turn on the shafts and drive fluid through the pump. As with other forms of rotary pumps, the clearance betwixt moving parts and the pump's casing is minimal.

Progressing cavity pump [edit]

Widely used for pumping hard materials, such as sewage sludge contaminated with large particles, this pump consists of a helical rotor, well-nigh x times as long as its width. This tin can be visualized as a central core of bore x with, typically, a curved screw wound effectually of thickness half x, though in reality information technology is manufactured in a single casting. This shaft fits inside a heavy-duty rubber sleeve, of wall thickness as well typically x. As the shaft rotates, the rotor gradually forces fluid upwards the rubber sleeve. Such pumps can develop very loftier pressure at low volumes.

Roots-type pumps [edit]

Named after the Roots brothers who invented it, this lobe pump displaces the liquid trapped between two long helical rotors, each fitted into the other when perpendicular at 90°, rotating inside a triangular shaped sealing line configuration, both at the point of suction and at the point of discharge. This design produces a continuous flow with equal volume and no vortex. It can piece of work at low pulsation rates, and offers gentle performance that some applications require.

Applications include:

- High capacity industrial air compressors.

- Roots superchargers on internal combustion engines.

- A brand of ceremonious defense siren, the Federal Signal Corporation's Thunderbolt.

Peristaltic pump [edit]

A peristaltic pump is a type of positive-displacement pump. It contains fluid within a flexible tube fitted inside a circular pump casing (though linear peristaltic pumps have been fabricated). A number of rollers, shoes, or wipers attached to a rotor compresses the flexible tube. As the rotor turns, the part of the tube under pinch closes (or occludes), forcing the fluid through the tube. Additionally, when the tube opens to its natural state subsequently the passing of the cam it draws (restitution) fluid into the pump. This process is called peristalsis and is used in many biological systems such as the alimentary canal.

Plunger pumps [edit]

Plunger pumps are reciprocating positive-displacement pumps.

These consist of a cylinder with a reciprocating plunger. The suction and discharge valves are mounted in the head of the cylinder. In the suction stroke, the plunger retracts and the suction valves open causing suction of fluid into the cylinder. In the forward stroke, the plunger pushes the liquid out of the belch valve. Efficiency and mutual problems: With only ane cylinder in plunger pumps, the fluid flow varies between maximum menstruation when the plunger moves through the middle positions, and naught menstruum when the plunger is at the end positions. A lot of energy is wasted when the fluid is accelerated in the piping system. Vibration and h2o hammer may be a serious problem. In general, the problems are compensated for past using ii or more cylinders not working in phase with each other.

Triplex-style plunger pumps [edit]

Triplex plunger pumps use 3 plungers, which reduces the pulsation of single reciprocating plunger pumps. Adding a pulsation dampener on the pump outlet can further smooth the pump ripple, or ripple graph of a pump transducer. The dynamic relationship of the high-pressure fluid and plunger generally requires high-quality plunger seals. Plunger pumps with a larger number of plungers take the benefit of increased flow, or smoother period without a pulsation damper. The increase in moving parts and crankshaft load is i drawback.

Car washes often utilise these triplex-style plunger pumps (perhaps without pulsation dampers). In 1968, William Bruggeman reduced the size of the triplex pump and increased the lifespan so that motorcar washes could employ equipment with smaller footprints. Durable high-pressure level seals, low-force per unit area seals and oil seals, hardened crankshafts, hardened connecting rods, thick ceramic plungers and heavier duty brawl and roller bearings amend reliability in triplex pumps. Triplex pumps at present are in a myriad of markets across the earth.

Triplex pumps with shorter lifetimes are commonplace to the home user. A person who uses a dwelling house pressure washer for x hours a yr may be satisfied with a pump that lasts 100 hours between rebuilds. Industrial-class or continuous duty triplex pumps on the other end of the quality spectrum may run for as much as two,080 hours a twelvemonth.[18]

The oil and gas drilling industry uses massive semi trailer-transported triplex pumps called mud pumps to pump drilling mud, which cools the drill bit and carries the cuttings dorsum to the surface.[19] Drillers use triplex or fifty-fifty quintuplex pumps to inject water and solvents deep into shale in the extraction process called fracking.[20]

Compressed-air-powered double-diaphragm pumps [edit]

One modern application of positive-displacement pumps is compressed-air-powered double-diaphragm pumps. Run on compressed air, these pumps are intrinsically safe by design, although all manufacturers offering ATEX certified models to comply with manufacture regulation. These pumps are relatively inexpensive and can perform a wide variety of duties, from pumping water out of bunds to pumping hydrochloric acid from secure storage (dependent on how the pump is manufactured – elastomers / body structure). These double-diaphragm pumps can handle viscous fluids and abrasive materials with a gentle pumping procedure ideal for transporting shear-sensitive media.[21]

Rope pumps [edit]

Devised in China as chain pumps over m years ago, these pumps can be made from very unproblematic materials: A rope, a bicycle and a PVC pipe are sufficient to make a simple rope pump. Rope pump efficiency has been studied by grassroots organizations and the techniques for making and running them have been continuously improved.[22]

Impulse pumps [edit]

Impulse pumps utilize force per unit area created by gas (usually air). In some impulse pumps the gas trapped in the liquid (usually water), is released and accumulated somewhere in the pump, creating a pressure that can push role of the liquid upwards.

Conventional impulse pumps include:

- Hydraulic ram pumps – kinetic energy of a depression-head water supply is stored temporarily in an air-bubble hydraulic accumulator, then used to drive h2o to a higher head.

- Pulser pumps – run with natural resource, by kinetic energy only.

- Airlift pumps – run on air inserted into pipage, which pushes the water up when bubbles move upwards

Instead of a gas aggregating and releasing cycle, the pressure can be created past burning of hydrocarbons. Such combustion driven pumps directly transmit the impulse from a combustion event through the actuation membrane to the pump fluid. In gild to allow this direct transmission, the pump needs to be almost entirely made of an elastomer (e.k. silicone prophylactic). Hence, the combustion causes the membrane to expand and thereby pumps the fluid out of the side by side pumping chamber. The start combustion-driven soft pump was developed by ETH Zurich.[23]

Hydraulic ram pumps [edit]

A hydraulic ram is a water pump powered past hydropower.[24]

Information technology takes in water at relatively low pressure level and loftier menstruum-rate and outputs water at a higher hydraulic-head and lower menstruum-rate. The device uses the water hammer effect to develop pressure that lifts a portion of the input h2o that powers the pump to a point higher than where the water started.

The hydraulic ram is sometimes used in remote areas, where at that place is both a source of low-head hydropower, and a need for pumping water to a destination higher in summit than the source. In this situation, the ram is often useful, since it requires no exterior source of power other than the kinetic energy of flowing water.

Velocity pumps [edit]

Rotodynamic pumps (or dynamic pumps) are a type of velocity pump in which kinetic energy is added to the fluid by increasing the menstruum velocity. This increase in energy is converted to a gain in potential energy (pressure) when the velocity is reduced prior to or as the menses exits the pump into the discharge pipe. This conversion of kinetic energy to force per unit area is explained by the First law of thermodynamics, or more than specifically by Bernoulli'southward principle.

Dynamic pumps can be further subdivided according to the means in which the velocity gain is achieved.[25]

These types of pumps have a number of characteristics:

- Continuous energy

- Conversion of added energy to increase in kinetic free energy (increase in velocity)

- Conversion of increased velocity (kinetic free energy) to an increase in pressure caput

A practical difference between dynamic and positive-displacement pumps is how they operate under closed valve conditions. Positive-displacement pumps physically readapt fluid, so closing a valve downstream of a positive-deportation pump produces a continual force per unit area build upward that can cause mechanical failure of pipeline or pump. Dynamic pumps differ in that they can be safely operated under airtight valve conditions (for brusk periods of time).

Radial-flow pumps [edit]

Such a pump is also referred to as a centrifugal pump. The fluid enters along the axis or eye, is accelerated past the impeller and exits at correct angles to the shaft (radially); an example is the centrifugal fan, which is ordinarily used to implement a vacuum cleaner. Another type of radial-catamenia pump is a vortex pump. The liquid in them moves in tangential direction around the working cycle. The conversion from the mechanical energy of motor into the potential free energy of menses comes by ways of multiple whirls, which are excited by the impeller in the working channel of the pump. Generally, a radial-flow pump operates at higher pressures and lower flow rates than an axial- or a mixed-flow pump.

Centric-flow pumps [edit]

These are besides referred to as All fluid pumps. The fluid is pushed outward or inwards to move fluid axially. They operate at much lower pressures and college flow rates than radial-catamenia (centrifugal) pumps. Axial-flow pumps cannot be run up to speed without special precaution. If at a low menses charge per unit, the full head ascent and high torque associated with this pipe would mean that the starting torque would have to get a function of dispatch for the whole mass of liquid in the pipe system. If at that place is a big corporeality of fluid in the organization, accelerate the pump slowly.[26]

Mixed-menstruation pumps function as a compromise betwixt radial and axial-flow pumps. The fluid experiences both radial acceleration and lift and exits the impeller somewhere between 0 and 90 degrees from the centric direction. Every bit a consequence mixed-flow pumps operate at higher pressures than centric-flow pumps while delivering higher discharges than radial-flow pumps. The exit angle of the menses dictates the force per unit area head-belch characteristic in relation to radial and mixed-period.

Regenerative turbine pumps [edit]

Regenerative Turbine Pump Animatic

Regenerative turbine pump rotor and housing, one⁄iii horsepower (0.25 kW). 85 millimetres (three.three in) diameter impeller rotates counter-clockwise. Left: inlet, right: outlet. .4 millimetres (0.016 in) thick vanes on 4 millimetres (0.sixteen in) centers

Also known as drag, friction, liquid-ring pump, peripheral, side-aqueduct, traction, turbulence, or vortex pumps, regenerative turbine pumps are class of rotodynamic pump that operates at loftier head pressures, typically iv–20 bars (four.1–20.4 kgf/cmtwo; 58–290 psi).[27]

The pump has an impeller with a number of vanes or paddles which spins in a cavity. The suction port and pressure ports are located at the perimeter of the cavity and are isolated by a bulwark called a stripper, which allows simply the tip channel (fluid between the blades) to recirculate, and forces whatever fluid in the side channel (fluid in the cavity exterior of the blades) through the pressure port. In a regenerative turbine pump, every bit fluid spirals repeatedly from a vane into the side channel and back to the next vane, kinetic energy is imparted to the periphery,[27] thus pressure builds with each spiral, in a fashion similar to a regenerative blower.[28] [29] [30]

As regenerative turbine pumps cannot become vapor locked, they are commonly applied to volatile, hot, or cryogenic fluid send. Yet, as tolerances are typically tight, they are vulnerable to solids or particles causing jamming or rapid clothing. Efficiency is typically low, and pressure level and power consumption typically decrease with flow. Additionally, pumping direction can exist reversed past reversing direction of spin.[30] [28] [31]

Eductor-jet pump [edit]

This uses a jet, ofttimes of steam, to create a low pressure. This low pressure sucks in fluid and propels information technology into a higher pressure region.

Gravity pumps [edit]

Gravity pumps include the syphon and Heron'southward fountain. The hydraulic ram is also sometimes called a gravity pump; in a gravity pump the water is lifted by gravitational force and so called gravity pump

Steam pumps [edit]

Steam pumps take been for a long time mainly of historical interest. They include any type of pump powered past a steam engine and also pistonless pumps such as Thomas Savery'due south or the Pulsometer steam pump.

Recently at that place has been a resurgence of interest in depression ability solar steam pumps for use in smallholder irrigation in developing countries. Previously small-scale steam engines accept non been viable because of escalating inefficiencies as vapour engines decrease in size. Still the use of modern engineering science materials coupled with culling engine configurations has meant that these types of organization are now a cost-effective opportunity.

Valveless pumps [edit]

Valveless pumping assists in fluid send in diverse biomedical and engineering systems. In a valveless pumping system, no valves (or physical occlusions) are present to regulate the menses direction. The fluid pumping efficiency of a valveless system, still, is not necessarily lower than that having valves. In fact, many fluid-dynamical systems in nature and engineering more than or less rely upon valveless pumping to send the working fluids therein. For instance, blood apportionment in the cardiovascular organization is maintained to some extent even when the centre's valves fail. Meanwhile, the embryonic vertebrate heart begins pumping blood long before the development of discernible chambers and valves. In microfluidics, valveless impedance pumps have been fabricated, and are expected to be particularly suitable for treatment sensitive biofluids. Ink jet printers operating on the piezoelectric transducer principle besides apply valveless pumping. The pump chamber is emptied through the press jet due to reduced flow impedance in that direction and refilled by capillary action.

Pump repairs [edit]

Derelict windmill connected to water pump with water storage tank in the foreground

Examining pump repair records and mean time between failures (MTBF) is of swell importance to responsible and conscientious pump users. In view of that fact, the preface to the 2006 Pump User'south Handbook alludes to "pump failure" statistics. For the sake of convenience, these failure statistics often are translated into MTBF (in this case, installed life before failure).[32]

In early 2005, Gordon Buck, John Crane Inc.'southward chief engineer for field operations in Baton Rouge, Louisiana, examined the repair records for a number of refinery and chemical plants to obtain meaningful reliability data for centrifugal pumps. A total of 15 operating plants having nearly xv,000 pumps were included in the survey. The smallest of these plants had almost 100 pumps; several plants had over 2000. All facilities were located in the Us. In add-on, considered as "new", others as "renewed" and however others as "established". Many of these plants—but not all—had an alliance system with John Crane. In some cases, the alliance contract included having a John Crane Inc. technician or engineer on-site to coordinate various aspects of the plan.

Non all plants are refineries, yet, and different results occur elsewhere. In chemic plants, pumps have historically been "throw-abroad" items as chemic attack limits life. Things have improved in recent years, but the somewhat restricted space available in "old" DIN and ASME-standardized stuffing boxes places limits on the type of seal that fits. Unless the pump user upgrades the seal sleeping room, the pump only accommodates more compact and elementary versions. Without this upgrading, lifetimes in chemical installations are generally around l to 60 percent of the refinery values.

Unscheduled maintenance is often 1 of the most significant costs of ownership, and failures of mechanical seals and bearings are among the major causes. Keep in mind the potential value of selecting pumps that toll more initially, but last much longer betwixt repairs. The MTBF of a better pump may exist one to four years longer than that of its not-upgraded counterpart. Consider that published average values of avoided pump failures range from US$2600 to US$12,000. This does not include lost opportunity costs. One pump burn occurs per k failures. Having fewer pump failures means having fewer destructive pump fires.

As has been noted, a typical pump failure, based on actual year 2002 reports, costs Us$five,000 on average. This includes costs for material, parts, labor and overhead. Extending a pump's MTBF from 12 to eighteen months would relieve United states$1,667 per year — which might be greater than the cost to upgrade the centrifugal pump'due south reliability.[32] [1] [33]

Applications [edit]

Pumps are used throughout club for a multifariousness of purposes. Early applications includes the use of the windmill or watermill to pump water. Today, the pump is used for irrigation, water supply, gasoline supply, air conditioning systems, refrigeration (unremarkably called a compressor), chemical movement, sewage motion, flood command, marine services, etc.

Because of the wide variety of applications, pumps have a plethora of shapes and sizes: from very large to very pocket-size, from treatment gas to treatment liquid, from high force per unit area to low force per unit area, and from high volume to low volume.

Priming a pump [edit]

Typically, a liquid pump tin't just draw air. The feed line of the pump and the internal body surrounding the pumping mechanism must first be filled with the liquid that requires pumping: An operator must introduce liquid into the organization to initiate the pumping. This is called priming the pump. Loss of prime number is commonly due to ingestion of air into the pump. The clearances and displacement ratios in pumps for liquids, whether sparse or more viscous, usually cannot displace air due to its compressibility. This is the case with well-nigh velocity (rotodynamic) pumps — for example, centrifugal pumps. For such pumps, the position of the pump should always be lower than the suction point, if not the pump should be manually filled with liquid or a secondary pump should be used until all air is removed from the suction line and the pump casing.

Positive–displacement pumps, however, tend to have sufficiently tight sealing between the moving parts and the casing or housing of the pump that they can be described as self-priming. Such pumps can also serve as priming pumps, so-called when they are used to fulfill that demand for other pumps in lieu of activeness taken by a human being operator.

Pumps as public h2o supplies [edit]

One sort of pump one time common worldwide was a hand-powered water pump, or 'bullpen pump'. It was commonly installed over community water wells in the days before piped water supplies.

In parts of the British Isles, it was often called the parish pump. Though such customs pumps are no longer common, people still used the expression parish pump to describe a identify or forum where matters of local interest are discussed.[37]

Because water from pitcher pumps is drawn direct from the soil, information technology is more than decumbent to contamination. If such h2o is not filtered and purified, consumption of information technology might lead to gastrointestinal or other water-borne diseases. A notorious instance is the 1854 Broad Street cholera outbreak. At the time it was not known how cholera was transmitted, but medico John Snow suspected contaminated water and had the handle of the public pump he suspected removed; the outbreak then subsided.

Modern hand-operated community pumps are considered the nigh sustainable depression-toll option for safe water supply in resources-poor settings, often in rural areas in developing countries. A mitt pump opens admission to deeper groundwater that is oftentimes not polluted and also improves the safety of a well by protecting the water source from contaminated buckets. Pumps such as the Afridev pump are designed to exist cheap to build and install, and like shooting fish in a barrel to maintain with simple parts. However, scarcity of spare parts for these type of pumps in some regions of Africa has diminished their utility for these areas.

Sealing multiphase pumping applications [edit]

Multiphase pumping applications, also referred to as tri-phase, accept grown due to increased oil drilling activity. In addition, the economics of multiphase product is bonny to upstream operations as it leads to simpler, smaller in-field installations, reduced equipment costs and improved production rates. In essence, the multiphase pump can adapt all fluid stream properties with one piece of equipment, which has a smaller footprint. Often, two smaller multiphase pumps are installed in serial rather than having just one massive pump.

For midstream and upstream operations, multiphase pumps tin be located onshore or offshore and can be connected to unmarried or multiple wellheads. Basically, multiphase pumps are used to transport the untreated menstruation stream produced from oil wells to downstream processes or gathering facilities. This means that the pump may handle a period stream (well stream) from 100 percent gas to 100 percent liquid and every imaginable combination in between. The period stream can also comprise abrasives such equally sand and dirt. Multiphase pumps are designed to operate under changing or fluctuating process conditions. Multiphase pumping also helps eliminate emissions of greenhouse gases as operators strive to minimize the flaring of gas and the venting of tanks where possible.[38]

Types and features of multiphase pumps [edit]

Helico-axial (centrifugal) [edit]

A rotodynamic pump with i single shaft that requires ii mechanical seals, this pump uses an open up-type axial impeller. It is ofttimes called a Poseidon pump, and tin be described equally a cross between an centric compressor and a centrifugal pump.

Twin-screw (positive-displacement) [edit]

The twin-screw pump is constructed of two inter-meshing screws that move the pumped fluid. Twin spiral pumps are frequently used when pumping weather condition contain high gas volume fractions and fluctuating inlet conditions. Four mechanical seals are required to seal the ii shafts.

Progressive cavity (positive-deportation) [edit]

When the pumping application is not suited to a centrifugal pump, a progressive crenel pump is used instead.[39] Progressive cavity pumps are single-screw types typically used in shallow wells or at the surface. This pump is mainly used on surface applications where the pumped fluid may incorporate a considerable corporeality of solids such as sand and dirt. The volumetric efficiency and mechanical efficiency of a progressive cavity pump increases as the viscosity of the liquid does.[39]

Electrical submersible (centrifugal) [edit]

These pumps are basically multistage centrifugal pumps and are widely used in oil well applications as a method for artificial lift. These pumps are usually specified when the pumped fluid is mainly liquid.

Buffer tank A buffer tank is oftentimes installed upstream of the pump suction nozzle in example of a slug catamenia. The buffer tank breaks the free energy of the liquid slug, smooths any fluctuations in the incoming flow and acts as a sand trap.

Equally the name indicates, multiphase pumps and their mechanical seals tin can encounter a big variation in service conditions such as changing procedure fluid limerick, temperature variations, high and low operating pressures and exposure to abrasive/erosive media. The claiming is selecting the appropriate mechanical seal arrangement and back up system to ensure maximized seal life and its overall effectiveness.[38] [forty] [41]

Specifications [edit]

Pumps are normally rated by horsepower, volumetric flow rate, outlet pressure in metres (or feet) of head, inlet suction in suction anxiety (or metres) of caput. The caput tin exist simplified as the number of feet or metres the pump can enhance or lower a column of water at atmospheric pressure.

From an initial blueprint point of view, engineers frequently use a quantity termed the specific speed to place the most suitable pump blazon for a detail combination of menstruation rate and caput.

Pumping ability [edit]

The ability imparted into a fluid increases the energy of the fluid per unit volume. Thus the power human relationship is between the conversion of the mechanical energy of the pump mechanism and the fluid elements within the pump. In general, this is governed by a series of simultaneous differential equations, known equally the Navier–Stokes equations. Nonetheless a more than simple equation relating only the different energies in the fluid, known as Bernoulli's equation can be used. Hence the power, P, required by the pump:

where Δp is the change in full pressure level between the inlet and outlet (in Pa), and Q, the volume flow-rate of the fluid is given in m3/due south. The total pressure level may have gravitational, static pressure and kinetic energy components; i.eastward. free energy is distributed between change in the fluid's gravitational potential energy (going up or down hill), modify in velocity, or change in static force per unit area. η is the pump efficiency, and may be given past the manufacturer's data, such every bit in the grade of a pump bend, and is typically derived from either fluid dynamics simulation (i.e. solutions to the Navier–Stokes for the particular pump geometry), or by testing. The efficiency of the pump depends upon the pump's configuration and operating conditions (such as rotational speed, fluid density and viscosity etc.)

For a typical "pumping" configuration, the work is imparted on the fluid, and is thus positive. For the fluid imparting the work on the pump (i.e. a turbine), the work is negative. Ability required to drive the pump is determined by dividing the output power by the pump efficiency. Furthermore, this definition encompasses pumps with no moving parts, such as a siphon.

Efficiency [edit]

Pump efficiency is defined every bit the ratio of the power imparted on the fluid by the pump in relation to the power supplied to bulldoze the pump. Its value is not fixed for a given pump, efficiency is a role of the discharge and therefore besides operating caput. For centrifugal pumps, the efficiency tends to increment with flow rate up to a point midway through the operating range (peak efficiency or All-time Efficiency Point (BEP) ) and then declines equally flow rates rise further. Pump performance data such every bit this is unremarkably supplied by the manufacturer before pump selection. Pump efficiencies tend to decline over time due to wear (due east.g. increasing clearances as impellers reduce in size).

When a system includes a centrifugal pump, an of import design upshot is matching the head loss-menstruation characteristic with the pump so that it operates at or close to the indicate of its maximum efficiency.

Pump efficiency is an important aspect and pumps should be regularly tested. Thermodynamic pump testing is one method.

Minimum flow protection [edit]

Near large pumps have a minimum period requirement beneath which the pump may be damaged past overheating, impeller clothing, vibration, seal failure, drive shaft harm or poor operation.[42] A minimum flow protection system ensures that the pump is not operated below the minimum catamenia rate. The system protects the pump even if it is shut-in or dead-headed, that is, if the discharge line is completely closed.[43]

The simplest minimum period organisation is a pipe running from the pump discharge line back to the suction line. This line is fitted with an orifice plate sized to allow the pump minimum flow to pass.[44] The arrangement ensures that the minimum flow is maintained, although it is wasteful as information technology recycles fluid even when the catamenia through the pump exceeds the minimum catamenia.

Schematic of pump minimum menstruum protection arrangement

A more sophisticated, but more plush, system (see diagram) comprises a flow measuring device (FE) in the pump discharge which provides a signal into a flow controller (FIC) which actuates a flow control valve (FCV) in the recycle line. If the measured flow exceeds the minimum flow so the FCV is closed. If the measured period falls beneath the minimum menstruum the FCV opens to maintain the minimum flowrate.[42]

As the fluids are recycled the kinetic energy of the pump increases the temperature of the fluid. For many pumps this added heat free energy is dissipated through the pipework. However, for large industrial pumps, such every bit oil pipeline pumps, a recycle cooler is provided in the recycle line to absurd the fluids to the normal suction temperature.[45] Alternatively the recycled fluids may be returned to upstream of the consign cooler in an oil refinery, oil final, or offshore installation.

References [edit]

- ^ a b Submersible slurry pumps in high demand. Engineeringnews.co.za. Retrieved on 2011-05-25.

- ^ Pump classifications. Fao.org. Retrieved on 2011-05-25.

- ^ Engineering Sciences Data Unit (2007). "Radial, mixed and axial flow pumps. Introduction" (PDF).

- ^ Engineer, Waqar (26 April 2021). "Positive displacement pump". Mechanical oost.

- ^ "Understanding positive displacement pumps | PumpScout". Retrieved 2018-01-03 .

- ^ "The Volumetric Efficiency of Rotary Positive Deportation Pumps". www.pumpsandsystems.com. 2015-05-21. Retrieved 2019-03-27 .

- ^ inc., elyk innovation. "Positive Displacement Pumps - LobePro Rotary Pumps". world wide web.lobepro.com . Retrieved 2018-01-03 .

- ^ "Eccentric Disc Pumps". PSG.

- ^ "Hollow Disc Rotary Pumps". APEX Equipment.

- ^ "Chiliad Pompe | Hollow Oscillating Disk Pumps | self priming pumps | reversible pumps | depression-speed pumps". www.mpompe.com.

- ^ "Hollow disc pumps". Pump Supplier Bedu.

- ^ "3P PRINZ - Hollow rotary deejay pumps - Pompe 3P - Made in Italy". www.3pprinz.com.

- ^ "Hollow Disc Pump". magnatexpumps.com.

- ^ "Hollow Rotary Disc Pumps". November 4, 2014.

- ^ "FAQs and Favorites - Espresso Machines". www.dwelling-barista.com.

- ^ "The Pump: The Middle of Your Espresso Car". Clive Coffee.

- ^ Inc., Triangle Pump Components. "What Is Volumetric Efficiency?". Retrieved 2018-01-03 .

- ^ "Definitive Guide: Pumps Used in Pressure level Washers". The Force per unit area Washr Review . Retrieved May 14, 2016.

- ^ "Drilling Pumps". Gardner Denver.

- ^ "Stimulation and Fracturing pumps: Reciprocating, Quintuplex Stimulation and Fracturing Pump" Archived 2014-02-22 at the Wayback Machine. Gardner Denver.

- ^ Admin. "Advantages of an Air Operated Double Diaphragm Pump". Retrieved 2018-01-03 .

- ^ Tanzania water Archived 2012-03-31 at the Wayback Machine blog – case of grassroots researcher telling about his study and piece of work with the rope pump in Africa.

- ^ C.M. Schumacher, 1000. Loepfe, R. Fuhrer, R.North. Grass, and West.J. Stark, "3D printed lost-wax casted soft silicone monoblocks enable heart-inspired pumping by internal combustion," RSC Advances, Vol. 4, pp. 16039–16042, 2014.

- ^ Demirbas, Ayhan (2008-11-14). Biofuels: Securing the Planet's Hereafter Energy Needs. Springer Science & Business organization Media. ISBN9781848820111.

- ^ Welcome to the Hydraulic Establish Archived 2011-07-27 at the Wayback Machine. Pumps.org. Retrieved on 2011-05-25.

- ^ "Radial, mixed and axial flow pumps" (PDF). Establishment of Diploma Marine Engineers, Bangladesh. June 2003. Retrieved 2017-08-18 .

- ^ a b Quail F, Scanlon T, Stickland M (2011-01-11). "Design optimisation of a regenerative pump using numerical and experimental techniques" (PDF). International Journal of Numerical Methods for Oestrus & Fluid Flow. 21: 95–111. doi:10.1108/09615531111095094. Retrieved 2021-07-21 .

- ^ a b "Regenerative Turbine Pump". rothpump.com . Retrieved 30 April 2021.

- ^ Rajmane, M. Satish; Kallurkar, South.P. (May 2015). "CFD Assay of Domestic Centrifugal Pump for Operation Enhancement". International Research Journal of Engineering and Technology. 02 / #02. Retrieved 30 Apr 2021.

- ^ a b "Regenerative turbine pumps: product brochure" (PDF). PSG Dover: Ebsra. pp. 3-four-7. Retrieved xxx April 2021.

- ^ "Regenerative Turbine Pump vs Centrifugal Pump". Dyna Flow Engineering . Retrieved thirty Apr 2021.

- ^ a b Pump Statistics Should Shape Strategies. Mt-online.com 1 October 2008. Retrieved 24 September 2014.

- ^ Wasser, Goodenberger, Jim and Bob (Nov 1993). "Extended Life, Zero Emissions Seal for Procedure Pumps". John Crane Technical Report. Routledge. TRP 28017.

- ^ Donald Routledge Hill, "Mechanical Technology in the Medieval Near Eastward", Scientific American, May 1991, pp. 64-ix (cf. Donald Loma, Mechanical Engineering science Archived 25 December 2007 at the Wayback Machine)

- ^ Ahmad Y. al-Hassan. "The Origin of the Suction Pump: al-Jazari 1206 A.D." Archived from the original on 26 February 2008. Retrieved 16 July 2008.

- ^ Hill, Donald Routledge (1996). A History of Engineering in Classical and Medieval Times. London: Routledge. p. 143. ISBN0-415-15291-7.

- ^ "Online Dictionary – Parish Pump". Retrieved 2010-eleven-22 .

- ^ a b Sealing Multiphase Pumping Applications | Seals. Pump-zone.com. Retrieved on 2011-05-25.

- ^ a b "When to employ Progressive Cavity Pumps". www.libertyprocess.com . Retrieved 2017-08-xviii .

- ^ John Crane Seal Picket – John Crane Increases Production Capabilities with Auto that Streamlines Four Machining Functions into One Archived 2010-11-27 at the Wayback Machine. Sealsentinel.com. Retrieved on 2011-05-25.

- ^ Vacuum pump new on SA market. Engineeringnews.co.za. Retrieved on 2011-05-25.

- ^ a b Crane Technology. "minimum catamenia featherbed line". Crane Engineering . Retrieved 25 January 2021.

{{cite web}}: CS1 maint: url-status (link) - ^ Gas Processors Suppliers Association (2004). GPSA Technology Data Book (12 ed.). Tulsa: GPSA. pp. Chapter 7 Pumps and hydraulic turbines.

- ^ Pump Industry. "4 methods for maintaining minimum flow atmospheric condition". Pump Industry . Retrieved 25 January 2021.

{{cite web}}: CS1 maint: url-status (link) - ^ Beat out, Shearwater P&IDs dated 1997

Further reading [edit]

- Australian Pump Manufacturers' Association. Australian Pump Technical Handbook, 3rd edition. Canberra: Australian Pump Manufacturers' Clan, 1987. ISBN 0-7316-7043-4.

- Hicks, Tyler G. and Theodore W. Edwards. Pump Application Engineering. McGraw-Hill Book Visitor.1971. ISBN 0-07-028741-4

- Karassik, Igor, ed. (2007). Pump Handbook (4 ed.). McGraw Hill. ISBN9780071460446.

- Robbins, L. B. "Homemade Water Pressure Systems". Popular Science, February 1919, pages 83–84. Commodity about how a homeowner tin can hands build a pressurized abode water organization that does not use electricity.

| | Wikimedia Eatables has media related to Pumps. |

0 Response to "How Does an Old Fashioned Water Pump Work"

Post a Comment